The Best Strategy To Use For Sheet Metal Laser Cutter

The Best Strategy To Use For Sheet Metal Laser Cutter

Blog Article

In terms of contemporary producing, the precision and effectiveness of laser reducing engineering are definitely video game-modifying. Laser chopping machines have revolutionized industries by supplying a technique of chopping elements with unparalleled precision. In case you’ve ever marveled at the intricate patterns on metallic or wondered how complicated shapes are produced so seamlessly, it’s usually the operate of the industrial laser reducing equipment.

Permit’s get started with the basics: a laser cutter is usually a tool that employs a laser beam to cut products. This beam is extremely centered and generates high temperatures to soften or vaporize the material, generating precise cuts. Not like regular procedures, which might use mechanical blades, a laser cutter provides a degree of precision that is sort of unmatched. Picture wanting to carve a fragile pattern having a hammer—Evidently, a laser cutter is a great deal a lot more refined!

Industrial laser cutting takes this technological innovation to the next level, providing solutions for giant-scale operations. These equipment are created to deal with significant products and superior manufacturing volumes, making sure that even by far the most demanding initiatives are concluded with large efficiency. Imagine it as being the difference between utilizing a precision knife for fragile paper crafts and a strong observed for cutting by way of thick Wooden.

Laser Cutting Services Can Be Fun For Anyone

On the planet of CNC laser reducing, the “CNC” means Laptop Numerical Management. This engineering permits automatic and really exact cuts by adhering to digital models. In the event you’ve ever utilised a pc to attract then found that drawing come to life, CNC laser chopping performs in the same way, translating electronic layouts into Actual physical cuts. It’s like aquiring a Digital designer While using the precision of the laser.

On the planet of CNC laser reducing, the “CNC” means Laptop Numerical Management. This engineering permits automatic and really exact cuts by adhering to digital models. In the event you’ve ever utilised a pc to attract then found that drawing come to life, CNC laser chopping performs in the same way, translating electronic layouts into Actual physical cuts. It’s like aquiring a Digital designer While using the precision of the laser.Facts About Laser Cutting Equipment Uncovered

Precision laser reducing is not pretty much generating cuts; it’s about earning them correct every single time. The laser may be modified to obtain distinctive depths and widths, ensuring that every Slash is exactly wherever it ought to be. This can be vital for apps exactly where even a slight deviation could lead on to important issues. Visualize it like a surgeon’s scalpel, where precision is not just important but Certainly important.

Precision laser reducing is not pretty much generating cuts; it’s about earning them correct every single time. The laser may be modified to obtain distinctive depths and widths, ensuring that every Slash is exactly wherever it ought to be. This can be vital for apps exactly where even a slight deviation could lead on to important issues. Visualize it like a surgeon’s scalpel, where precision is not just important but Certainly important.Laser slicing devices comes in numerous kinds, Each individual tailor-made to unique needs. Irrespective of whether You will need a modest desktop model for hobby initiatives or an enormous industrial equipment for manufacturing facility use, there’s a laser chopping Answer out there for you personally. These devices fluctuate in electric power, speed, and abilities, so it’s crucial to select the appropriate a single for your personal particular software.

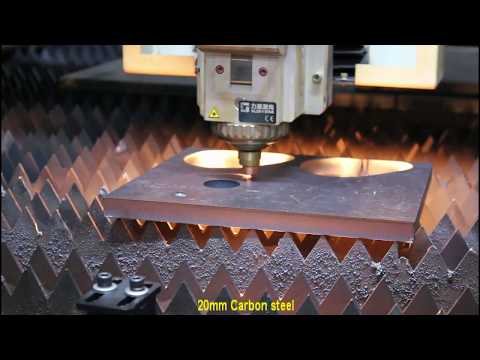

Sheet metallic laser cutters can be a special category of laser cutting equipment created specifically for reducing metal sheets. These are greatly Utilized in industries ranging from automotive to aerospace due to their power to manage metallic with precision and velocity. Photograph a sheet of metal just like a blank canvas, and also the laser cutter because the artist who results in advanced and beautiful styles with remarkable accuracy.

Laser chopping solutions are A further vital aspect of this know-how. Not All people desires to invest in their very own laser slicing device, particularly if they only have to have occasional cuts or deficiency the Place for these types of equipment. Numerous companies give laser slicing products and services in which you can deliver your designs and also have them Slash with substantial precision. It’s like outsourcing your artwork to a talented Skilled.

Laser reducing programs more details integrate different elements to provide the specified success. From the laser source to your cutting bed, along with the control program, each and every Component of the process works with each other to make sure a flawless Procedure. It’s a bit like a symphony orchestra, the place Every musician has a certain position, and only by working alongside one another do they develop a harmonious efficiency.

With regards to laser reducing technological innovation, the evolution continues to be rapid and extraordinary. To begin with employed predominantly for reducing metals, these devices now tackle a wide array of elements such as plastics, Wooden, as well as fabrics. This versatility helps make laser slicing engineering a valuable Resource in innumerable industries. Envision possessing a Swiss Army knife which will manage almost any material—this is what present day laser chopping technologies presents.

The accuracy of discover more laser chopping devices is really exceptional. They can Reduce resources to within microns on the meant design and style, ensuring that even probably the most intricate details are preserved. This standard of precision is particularly beneficial in industries wherever correct measurements are crucial. Visualize it because the distinction between a customized accommodate and off-the-rack clothes—the healthy is simply ideal each and every time.

Everything about Laser Cutting Machine

A different benefit of laser slicing technologies is its effectiveness. In contrast to classic cutting approaches Which may call for several steps or instruments, laser reducing typically completes the job in a single go. This not simply speeds up creation but in addition minimizes materials squander. It’s like getting a substantial-velocity prepare that will get you to the place speedily and competently with no avoidable stops.From the context of industrial apps, the robustness of laser slicing equipment is very important. These devices are developed to endure the calls for of constant Procedure, frequently running 24/7 in superior-volume configurations. Their longevity ensures constant overall performance and reliability, that's essential for retaining creation schedules. It’s like using a significant-duty truck that reliably provides goods working day following day.

On the list of amazing elements of laser cutting is its capability to develop thoroughly clean and precise edges. This minimizes the necessity for publish-processing, like sanding or finishing, that may be time-consuming and costly. The result is really a clean, concluded solution That always necessitates negligible added get the job done. Envision ending a craft project without having glue spills or tough edges—it’s that thoroughly clean!